What is Translucent Concrete?

Concrete is a building material that is durable, long life, and high-quality characteristics. Apart from having advantages the concrete mortar also has some disadvantages. One of the disadvantages is the unaesthetic appearance of concrete, which requires additional finishing. The development of new technology in concrete was in process and thus translucent concrete was invented. Silhouettes of objects and outlines of people are distinguished in this material, which is a unique design solution for the construction of buildings and structures. This concrete can be made by hand, which would reduce the cost.

A Hungarian Architect named A. Losonczi invented Translucent or transparent concrete. He studied the characteristics of the concrete and provided a solution to add structures with additional lighting in it. He saw that by adding these structures the strength of the concrete doesn’t get compromised. After fifteen years of experiments with concrete, the architect managed to introduce new material into the construction - transparent concrete (Litracon). It is composed of fine-grained composite materials and fiberglass.

Also Read: Cement vs Concrete

Large volumes of such concrete cannot be produced and as such, they have to be produced in the form of blocks.

The advantages are many but the main disadvantage is its cost which can run to thousands of dollars.

Features and Characteristics:

In addition to a unique appearance, transparent concretes have:

- high strength;

- water resistance;

- thermal insulation;

- soundproofing;

- the possibility of hand-made production.

The fiberglass in the composition makes the material more reinforced which in turn adds to its characteristics:

- moisture absorption up to six percent;

- frost resistance;

- bending strength;

- compressive strength.

The concrete is environmentally friendly which has been tested and certified. But it has a disadvantage of obtaining a light-conducting mixture that can be poured into the formwork at the construction site.

Also Read: Thumb Rules for Civil Engineers

The manufacturing process consists of layer-by-layer stacking of the components of the solution, after which solidification, the laid surface is treated with an additional composition, which will allow obtaining the desired light-conducting properties.

Light transmission is provided by the optical fiber included in the litracon. Light rays can be transmitted up to a distance of about 200cms through it. It. Due to the presence of fiber optic this concrete is resistant to fire and sudden temperature changes and UV radiation.

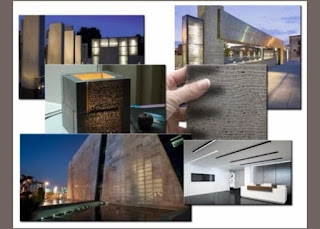

Walls made of transparent concrete are capable of letting in rays of natural light into the room during the daytime, illuminating the backyard area due to room lighting. Litracon can be found in black, white, and gray, matte or polished panels are also produced. Blocks of various sizes, with different colors and surface treatment methods, are made. And they are fixed with glue mixtures, mortars, and anchors.

Areas of Use:

- facades of buildings and structures;

- countertops;

- stairs;

- benches;

- Internal partitions.

Do it Yourself: Manufacturing process

Transparent concrete can be made easily, but this process should be carefully considered. The preparation of the transparent cement is slightly difficult as the proportions of the components should be correct. 4% of the fiber is used to get a light-guiding structure and secondly, these fibers should be laid strictly in one direction. The following method will show how you can prepare the material by your self:

- purified water;

- dried cement mixture with fine aggregate grains;

- The length of fiberglass fiber should correspond to the thickness of the board

- The Optical fiberglass should have a cross-section from ¼ to 3 mm, in length equal to the future thickness of the panels.

- Box preparation which should be a floating formwork that can move upward as the mortar hardens;

- This box is installed on a leveled horizontal surface and the prepared mixture is poured in a small volume to form a thin layer.

- The fiberglass is then placed in the filled solution and slightly sunk;

- Allow the solution to grab and then pour the next portion, after which another layer of fiberglass is placed in it;

- Repeat the above 2 steps repeat until the formwork is completely filled;

- The formwork is dismantled after the last layer of the poured mortar has solidified and then the sides of the blocks are ground and polished, from the side of perpendicularly located fiberglass.

The creation of a fine-grained concrete mortar consists of mixing one part of cement and three parts of sand. Part of the water is added based on the weight of the cement, and should not be more than half of its part. Then modifiers are added, some of which are determined according to the manufacturer's recommendations. The dry components are immersed in a mixer and mixed for one minute. As soon as the mixture becomes homogeneous, water is introduced and stirred for another five minutes.

After shaping the transparent concrete in the blocks, the finishing process is started. Stripping is carried out 2-3 days, and the manufactured block is left to stand in conditions of optimal humidity and temperature conditions. The further solidification process takes place in three to five days.

In order for the material to be able to transmit light rays, the side surfaces must be sanded.

Conclusion:

Litracon is a unique modern building material that has not only an attractive appearance but also high-quality characteristics. Its strength, reliability, and longevity are in no way inferior to ordinary concrete mortar.

Of the shortcomings, only the high cost of materials is observed, so if you want to save money, you can make a litracon with your own.

0 Comments